How Different Industries Use Dust Filter Bags

How Different Industries Use Dust Filter Bags

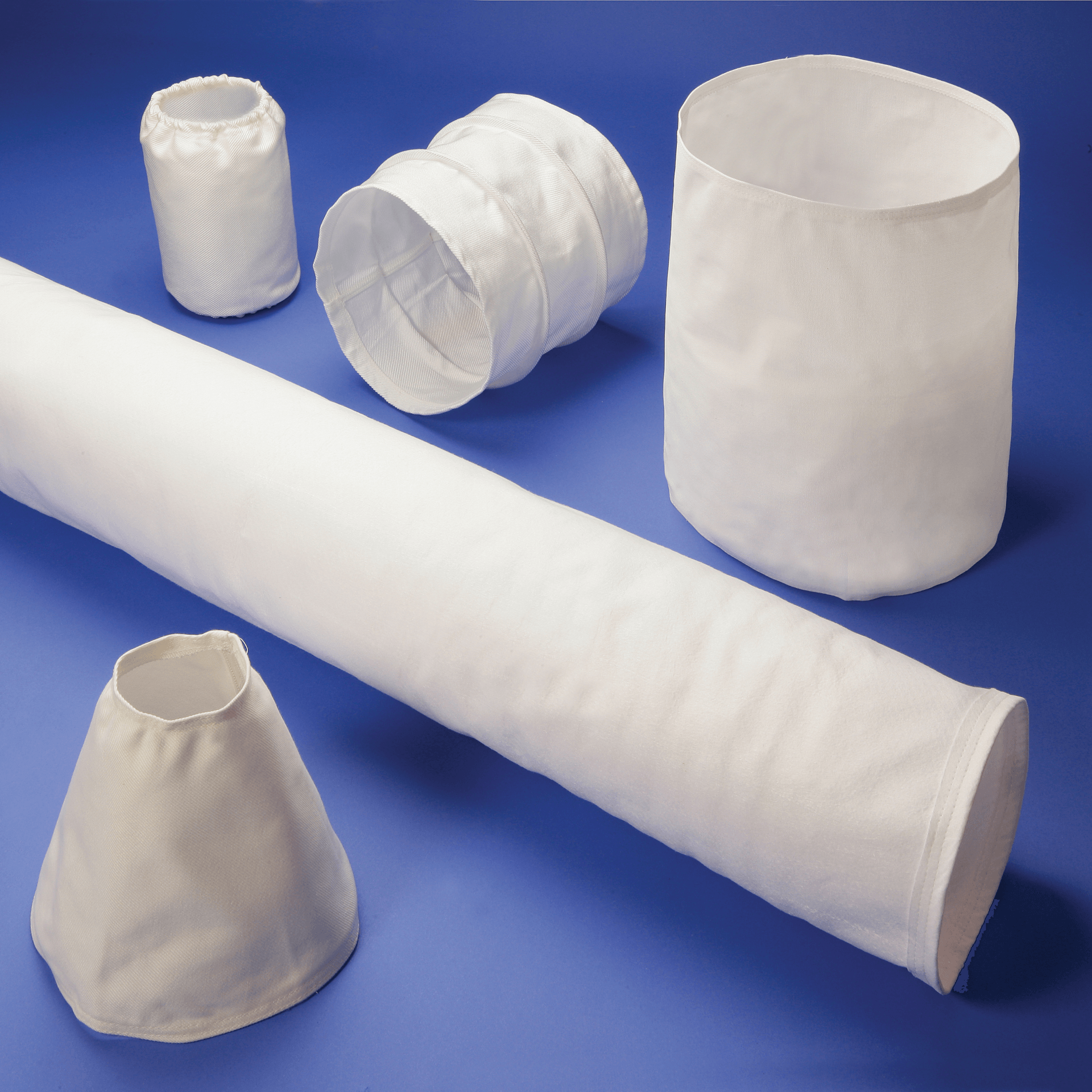

Dust filter bags are frequently used across a variety of industries. Dust filter bags can not only safeguard products, but they can create safe working environments. They are essential to the prosperity of many industries. In this guide, we’ll discuss the use of dust filter bags across industries and how exactly they are used.

Contact Us

336-372-2812

Manufacturing Industry

As you probably know, a manufacturing industry makes products from raw materials by means of manual labor or machinery. Manufacturing industries produce aircraft, automobiles, chemicals, clothing, computers, electronics, ships, steel, etc. Collectively, the manufacturing industry relies heavily on dust filter bags. However, the filtration needs do depend on the goods and products being made. In some instances, factories may need one giant bag whereas other plants may need numerous filters spread throughout the entire workspace. Filters should be placed near any equipment used within the factory.

Metals Industry:

The metals industry is one of the most wide-ranging manufacturing industries. However, this industry is united by the need for a filtration system. An efficient filtration system should be able to deliver increased airflow, effective energy utilization, and better temperature capabilities. The key to high-efficiency filtration in metal manufacturing industries is higher durability. You need a filter that works in the long-term and allows you the flexibility to meet demands.

Dust filter bags are primarily purchased for particulate collection. As the particulate is collected, the resistance to flow and differential pressure increases, causing higher fan energy costs. When the filter bags have holes, they are no longer as efficient at particulate capture. When the differential pressure is too high, the filter bag life is over. So, there needs to be an optimal balance of high filtration efficiency, low resistance to flow, and a long filter life. Additionally, these three aspects can reduce the number of times you’ll have to replace your industrial dust filter bags thereby lowering maintenance costs while increasing yield and greater productivity.

Asphalt and Cement Plants:

Most asphalt facilities use 400 to 600 filter bags in their collectors. These plants actually require frequent filter replacements because when you are running fuel oil or waste oil, the hydrocarbons quickly build up on the bag filter consequently restricting the air flow and lowering the tonnage output of the plant. Moreover, cement plants use a variety of dust filter bags such as pleated dust bags or cartridge filters.

Transportation Industry

Much dirt, dust, and debris are created by transportation. If you work within the transportation industry, you may be exposed to dirty engine components and poor air quality. That’s why there are more than 100 different kinds of dust filter bags utilized within the transportation industry. For example, vent bags can make the bulk loading process much easier when you’re loading up a truck or a railway car. There’s, also, custom trailer covers used to help relieve air while blowing product into a trailer. You definitely have your pick of dust filter bags which you can use to best suit your needs.

Pulse Jet Dust Collectors

Commonly used in the transportation industry are pulse jet dust collectors. These filter bags come in a variety of designs to meet various application needs. This filtration system operates via a rapid, high-pressure air jet cleaning which sends a blast of air through the bag that shatters and discharges the dust particles for disposal. The rapid pulse of air allows for continuous operation with the fan running. The standout features of the pulse jet models are their ability to be easily customized, capability to handle a vast range of temperatures and pressures, and their high collection efficiency.

Pharmaceutical Industry

The pharmaceutical industry utilizes extensive and precise regulations, making it one of the most highly controlled industries. Drug contamination is the worst thing that can happen to a pharmaceutical company as it can result in a devastating loss of money and a smear on their reputation. So, filtration and separation are an extremely vital process in the pharmaceutical industry. And with the right kinds of dust filter bags, contamination can be prevented. Filtration bags will protect the purity of your medications and keep your customers safe.

Dust from pharmaceuticals is generated mostly during the production and packaging process. The various steps of producing a drug, each produce a large amount of dust that needs to be removed as well. This dust can easily travel across the factory and contaminate both workers and products. So, intercepting this dissemination is essential.

The two types of dust collection systems primarily used by pharmaceutical companies are baghouse and cartridge. These filters don’t have to be replaced that often and are self-cleaning through pressure air spray.

Baghouse Dust Collection System

The most common form of dust collecting system is the baghouse. This system uses a fan to create a vacuum to force contaminants through a filter in a bag. Baghouse methods differ in how they clear their filters. The shaker method shakes the filter to remove the collected dust. The jet version uses a burst of air when a sensor detects the filter is full. The reverse air method forces fresh air through the filter. Regardless of which method is used, the dust is removed down into collection hoppers. Baghouse systems operate continuously to collect particles and the design of these systems allow for easy maintenance.

Cartridge Dust Collection System

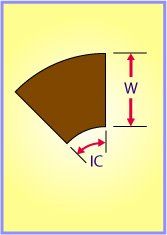

There are two main forms of cartridge dust collection systems - vertical and horizontal. With a horizontal system, the cartridge is placed horizontally. Dirty air enters the cartridge at high velocity. As the impure air passes through the cartridges, it is deposited on the external part of the filter. In cyclical fashion, a burst of air is injected into the cartridge which shakes the collected material into the hopper. The horizontal system allows for permanent and perfect cartridge alignment without yokes, sagging, or cracking.

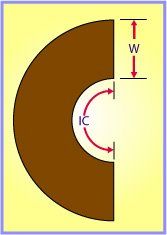

On the other hand, vertical cartridge dust collecting systems have the cartridges hung vertically. In these systems, the bags are replaced with cylindrical cartridges that are open on both ends and are lined with pleated filtering media. The air stream is forced through the outside of the cartridge to the inside. The cartridges are kept clean by compressed air blown into them, which removes built up dust that falls into the hopper below.

Food Processing and Industrial Baking Industry

The food processing industry uses all kinds of filtration methods including dust filter bags. Dust filter bags serve a great importance in this industry because they keep our food up to standards. Because foodborne illnesses are a threat, it’s essential food processing plants do their best to avoid potential contamination. In some cases, processing plants may even utilize custom filter bags. Things such as fabric ducts, fan covers, and catch cloths for conveyor belts can help you to keep your food from getting contaminated.

The main concern for dust collection systems in the food processing industry is transport, storage, and mixing, as these are areas that accumulate the most dust. Sugar, powders, flour, spices, and starch are materials that produce a lot of dust and need to be controlled and monitored as well. Filtration systems can be connected to equipment such as conveyors, packing equipment, mixers, and shelling machines.

Seed and Grain Operations

The amount of dust from seed and grain operations is so high that OSHA has outlined standards specified for these operations. Dust from seed and grain operations varies according to the type of materials being moved. It can be abrasive, sticky, or extremely fine. This is further complicated by the wide variety of equipment used in seed and grain operations. The most common form of dust collecting system for these operations is a baghouse collector. These filters are used for their high efficiency and reliability.

Pet Food

Just like human food, pet food needs to remain uncontaminated as well. In fact, pet food is handled with tighter restrictions and tougher regulations. Pet food manufacturers will typically use filter bags, blower intake filters, and pleated dust bags.

Woodworking & Furniture Industry

The woodworking industry has highly specific dust collection needs. Woodworking produces large volumes of saw dust and fumes. Hence dust filter bags are used to create a safe environment and ensure that woodworkers can breathe easily. Not only should the filtration system gather dust and chips, but it should be strong enough to filter clear air back in.

Lumber mills and sawmills require a different type of dust collection system than that which is used by a wood pellet manufacturer. Each type of operation requires a different form of collection system. Regardless of the type of woodworking operation, wood dust has been found to be the major cause of dust accidents. Wood dust easily ignites and spreads rapidly, which makes having a dust collection system essential.

Wood dust collection primarily uses three dust control systems - cyclones, baghouses, and cartridge collectors. Regardless of the system chosen, it must be designed and engineered to fit your operation and production process. Choosing the right type of dust collector can improve safety and save money. Industrial woodworking applications may include cutting, planing, sanding, routing, and sawing. The process and the type of wood help determine your dust collector options.

The Cyclone

Talk to the Filter Experts at PSAS, Inc.

Customer Focused. Solution Driven.

Talk to Our Filter Experts at PSAS, Inc.

Here at Parker Sales & Service, we can offer you your own custom dust filter bag. In our 60 years of fine service, we have built a notable reputation for our custom engineering.